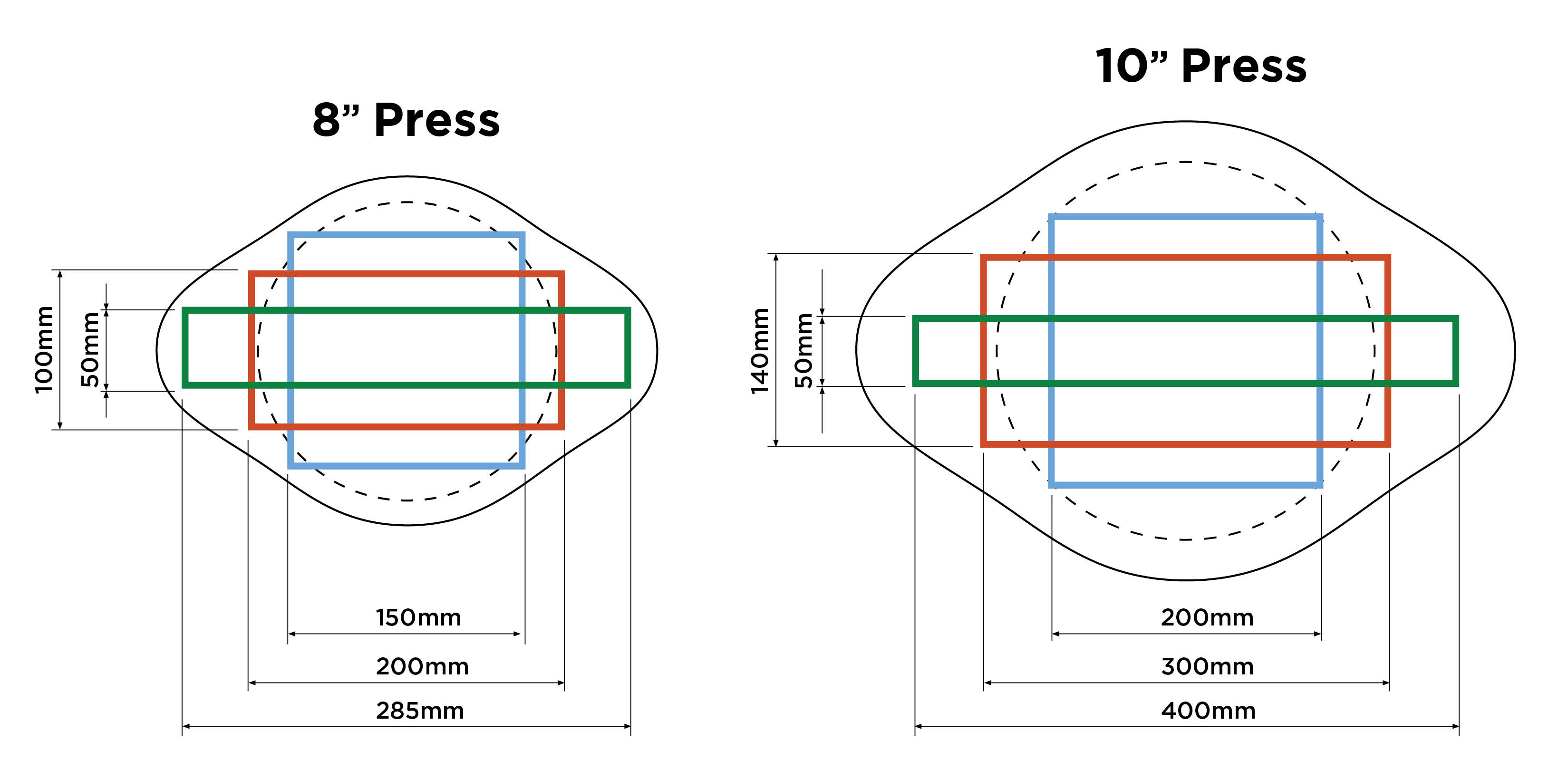

G.James currently operates four Australian-based extrusion presses generating a total production capacity of 3000 tonnes per month. Our plants employ the direct extrusion process where a heated aluminium billet is forced through a series (or stack) of specially milled plates to form and extrude the desired profile.

G.James is a trusted supplier to the Australian and Asia Pacific extrusion market servicing all levels of business within a wide range of industries. Significantly, the G.James Aluminium Products Division is committed to supporting our loyal customer base with the supply of quality Australian-produced extrusions through a program of ongoing investment in plant and equipment. We look forward to working with you.

In a world of elevated environmental awareness, the demand for materials with low or lower carbon emissions has never been greater.

In response, G.James Aluminium Products has introduced the EcoAL range of aluminium billets.

With two options available, EcoAL4 and EcoAL8, you can expand your green credentials by selecting a reduced emission-grade billet for your extrusions.

EcoAL billets are produced using innovative sources of power generation for the smelting process, the most energy-intensive process in the production of aluminium.